Accuracy is more than a catchphrase; it is the foundation of any quality process. The market of the global calibration services is expected to expand to approximately US$9.2 billion by 2033, starting with approximately US$6.2 billion in 2024, with a CAGR of just below 4.5. However, temperature calibrators are one of the most important tools that are ignored by many industries in ensuring that such precision is maintained. The slightest change in temperature overlooked can spill over into significant flaws in the quality of products, safety, and compliance.

To specialists in the industry, the question was not so much whether accuracy can be increased, but how to ensure it. With the increase in the manufacturing lines, process controls, and regulatory requirements, the use of temperature calibrators emerges as a strategic strength as opposed to a check. Go further, and discover how these instruments quietly ensure the safety of your operations, increase productivity, and keep faith in your measurements.

Understanding Why Accuracy Matters

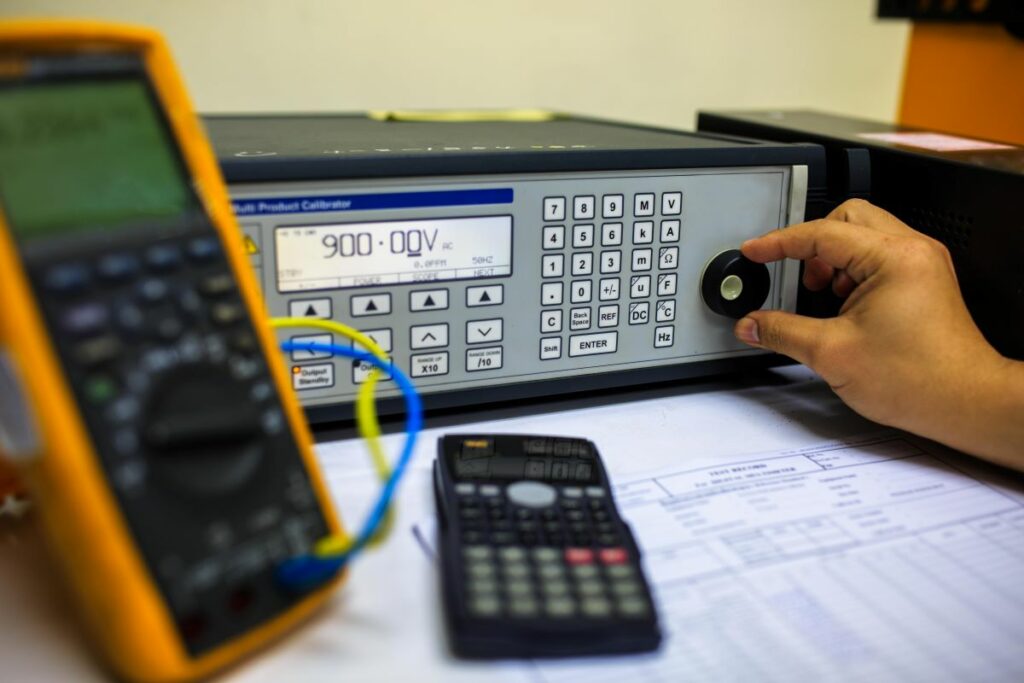

Temperature calibration has become one of the foundations of quality and safety in any industry where accuracy is the key determinant of performance. A single degree difference can change the chemical reactions, alter the material properties, or damage delicate equipment. This is why the main role is played by temperature calibrators that assist in checking and adjusting temperature sensors to make sure that every action is measured at the actual value.

When it comes to a pharmaceutical cleanroom or a steel manufacturing plant, precision affects all production stages. The temperature calibrators are used to test sensors over a wide temperature span: from cryogenic to high heat. This ensures that operations remain constant and within compliance. They have a very basic aim, which is to ensure that any mistakes are identified early enough before they become expensive. Through proper measurements, industries are able to minimize downtimes, enhance the quality of output, and maintain the consistency of processes in the long run.

The Major Advantages of Temperature Calibrators in Industry

Calibration of temperature using temperature calibrators has quantifiable benefits that are not restricted to periodic accuracy test. In the fields, they are necessary because of the following:

- Dependable sensor operation: It is possible to have regular calibration to make sure that the sensors can work at the limits and thus reduce false readings.

- Compliance with regulations: The approved calibration records help in compliance with ISO, ASTM and FDA regulations.

- Greater temperature capability: Contemporary temperature calibrators can certify temperatures of -180 o C to 3000 o C, and they are applicable in a wide range of applications.

- Process optimization: Continued temperature measurements aid in the smoother automation and minimize disruptions in the processing.

Common Pitfalls When Calibration Is Overlooked

- Sensor drift: Sensors are not calibrated within a specified time, and they start to show a wrong reading.

- Wrong calibrator type used: This reduces reliability because, in infrared sensors, a contact type calibrator should be used, or because incorrect temperature ranges are used.

- Late calibration periods: Uneven schedules put the likelihood of non-compliance and process fluctuation at risk.

- Operator error: The incompetent handling of temperature calibrators by untrained personnel can result in the introduction of measurement bias or errors in the data.

Best Practice Checklist for Integrating Temperature Calibrators

Calibration has to be systematic, traceable, and repeatable in order to be successfully implemented. Begin by identifying calibration intervals depending on the importance of a sensor to a process. The sensors that are used in energy, aerospace, or pharmaceuticals are highly precise and may require calibration every six months.

Next, align the right temperature calibrators with what you are using. Dry-blocks and baths are ideal calibrators of both thermocouples and RTDs (contact-type) and infrared sensors (non-contact blackbody calibrators). Traceability should always be made to accepted national or international standards.

Last but not least, keep a precise calibration record, date, method, and deviation record. This information is useful in determining patterns and performing proactive maintenance even before the problem occurs, so that the quality will be similar in all batches and processes.

Future Trends and Why Temperature Calibrators Will Matter Even More

The position of the temperature calibrators is changing with the emergence of the digital industries. Calibrators have also become smarter with the introduction of wireless networks and cloud storage, along with real-time data-sharing facilities. Such tools will ease documentation and speed up, and make audits transparent.

With the shift of industries to predictive maintenance systems, the use of calibrators will allow an instantaneous monitoring of the performance, as opposed to a periodic check. This change will decrease downtimes, lead to safety, and product consistency.

The regulations that will be adopted in the future will require stricter control of process temperatures. Investment in modern-day and sophisticated temperature calibrators would make organizations remain ahead of their time, making sure there is compliance, reliability, as well as confidence in each degree of measurement. The future is of systems that are precision-driven, and it is on calibration where precision commences.

Bridging Precision and Performance: The Role of Reliable Temperature Calibration

The precision is never attained in a single step, but requires regular calibration to be maintained. Trusted temperature calibrators will make sure that all the readings used in the industry are accurate and assist industries in reducing drift, remaining in compliance, and enhancing operational confidence.

To ensure that organizations consider how to simplify this process, Tempsens Tempsens will provide accredited calibrations and an extensive variety of contact and non-contact solutions that are in harmony with international standards. Their experience favors industries that want to have long-term dependability as opposed to quick-fix solutions. Because in any process that is founded on trust, precision is not merely a measure; it is guaranteed.